Measurement Traceability

Measurement Traceability

What is Measurement Traceability?

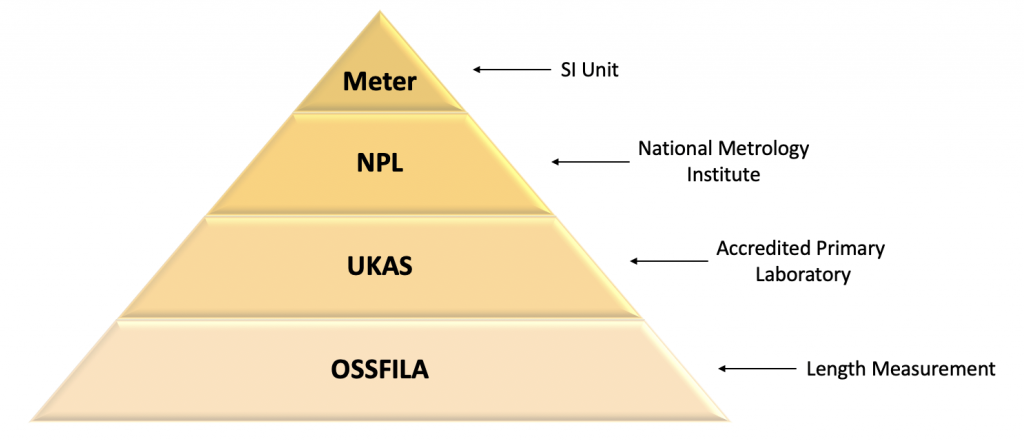

According to International Vocabulary of Metrology (VIM), Metrological Traceability or Measurement Traceability is a “property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty.” Therefore, VIM validates the credibility of specific lengths of products.

Why is Measurement Traceability Important for 3D printing parts?

Measurement traceability is important because it gives us confidence and assurance that our measurement results agree with national or international standards within the statement of uncertainty in measurement. Here in OSSFILA, we have certified measurement apparatus from accredited laboratories to ensure that we have minimum uncertainty for our 3D bone implants. This allows us to provide accurate and precise 3D printed implant products to ensure acute specificity to our customers.

Without traceability, a manufacturer can claim anything they want in an inspection test or quality report of the 3D printing parts. With measurement traceability to SI unit of length, we can minimize the risk of falling victim to fraudulent information and activities.

Measurement traceability of OSSFILA’s product.

All length measurement in OSSFILA Technology Limited are performed by length measuring equipment calibrated by accredited laboratory according to the above measurement traceability pyramid and well-trained personnel. The equipment we use are controlled by quality management system complied to international standard.